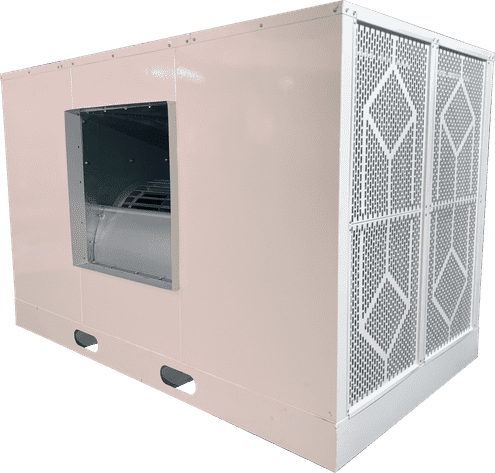

FCU (Fan Coil Unit)

FCU (Fan Coil Unit)

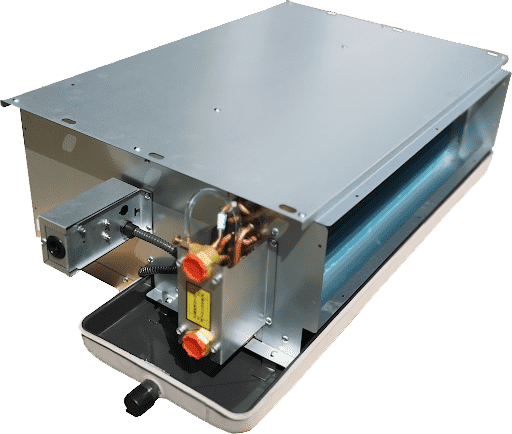

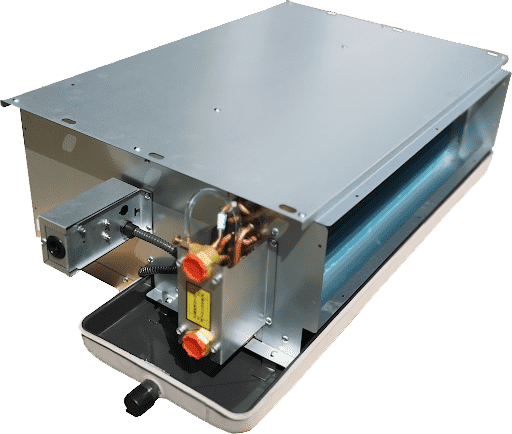

- Provides both hot and cool options with an electric PTC heater.

- Auto chilled water balancing functions are part of its capabilities.

- Features a low-noise easy access fan and a coated condensate drain pan.

- All required valves are built-in, ready to connect to chilled water networks.

- Includes 3-4 row heat exchanger coils and embedded chilled water control valves.

- Equipped with a direct-drive, long-life fan featuring a backward curve aluminum impeller.

- Available in concealed ceiling type, cassette type, wall-mounted, and floor- mounted types.

Key Features

Cooling & Heating Coils

Available in 3-row and 4-row configurations for efficient temperature control.

Low Noise Operation

Engineered for quiet performance, meeting JIS A 4008 standards.

Flexible Installation

Supports ceiling recessed, ceiling mount exposed, and floor-mounted setups.

Energy Efficiency

Optimized coil performance for better energy savings and operation.

Static Pressure Variants

Designed for various static pressure requirements, including high static models.

Durable Construction

Corrosion-resistant materials and sturdy casing ensure long-term reliability.

Smart Control System

Integrated AC240V wiring and advanced control panel for seamless operation.

Advanced Filtration

High-efficiency filters ensure clean air circulation and improved air quality.

Drain Pan Design

Prevents water leakage and enhances moisture management.

FCU (Fan Coil Unit)

Major Components

Top Industries We Specialized in

Download Our Catalogue & Explore Energy-Saving Technologies.

From evaporative coolers to adiabatic solutions and industrial power solutions, explore everything we offer in one simple download.

Related Products

Frequently Asked Questions (FAQS)

An FCU is a heating and cooling unit that circulates air within a space using a coil and fan system.

Models include WRC (Ceiling Recessed), WCRH (High Static), WC (Ceiling Mount Exposed), WF (Floor Mount Exposed), and WFR (Floor Mount Recessed).

It controls room temperature by cooling or heating air through a coil and distributing it with a fan.

They can be installed in offices, hotels, hospitals, commercial buildings, and residential spaces.

The FCUs come in 3-row and 4-row coil configurations for cooling and heating.

It supports various static pressure levels, including low and high static models for different applications.

The corrosion-resistant drain pan collects and drains condensation to prevent leaks.

Yes, it includes a high-efficiency air filter to improve indoor air quality.

The units are specially designed for low noise and tested in semi-anechoic rooms following JIS A 4008 standards.

The optimized coil design and variable static pressure settings help maximize energy efficiency.

Some models support multi-speed fans to adjust airflow based on cooling/heating needs.

It uses centrifugal fans for high efficiency and quiet operation.