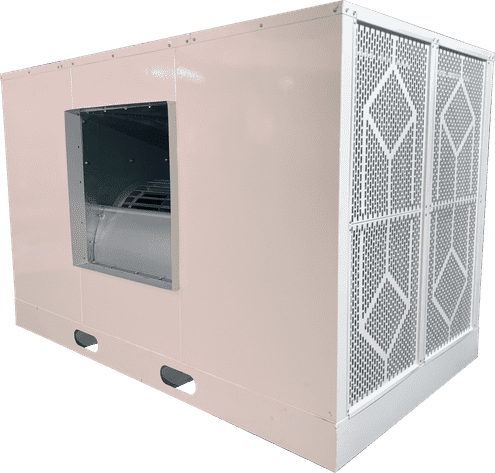

Air Handling Unit

- Choice between direct drive or belt drive.

- Options for microcontroller, PLC, HMI, and heat recovery seconds.

- Can incorporate chilled water control valves and sensors as needed.

- Includes pre-filters and fine filter sections as per design requirements.

- Features a 50mm double skin body panel with an aluminum profile reinforced frame.

- Sturdy, heavy-gauge coated base frame. Equipped with vibration isolators for fan blowers. Customized, modular design to meet specific application requirements.

Key Features

Humidity Control

AHUs offer humidification and dehumidification, maintaining optimal indoor humidity levels. This prevents mold, discomfort, and equipment damage.

Energy Efficiency

Modern AHUs integrate VSDs, energy recovery systems, and high-efficiency components for energy savings. This lowers utility costs, environmental impact, meeting codes and standards.

Major Components

Top Industries We Specialized in

Download Our Catalogue & Explore Energy-Saving Technologies.

From evaporative coolers to adiabatic solutions and industrial power solutions, explore everything we offer in one simple download.

Related Products

Frequently Asked Questions (FAQ)

The fans available are:

- Centrifugal Fans (Forward Fan, Backward Fan)

- Plug Fan

- Blower Motors

The available filters include:

- Aluminum filters

- Synthetic filters

- Pleated filters

- Low Velocity Filters (V-Filters)

- Bag Filters

- HEPA Filters

- Carbon Filters

The drain pan covers the entire coil section and is available in stainless steel.

AHUs filter out airborne particles, such as dust, pollen, and pollutants, before distributing the air. They may also incorporate humidification or dehumidification systems to maintain optimal humidity levels and remove excess moisture.

- AHU: Air Handling Unit

- FAHU: Fresh Air Handling Unit

These are components of HVAC systems responsible for circulating and conditioning air.

The catalog lists different access panels and doors designed for fan coil units and filter sections, categorized into unit sizes from WM2 to WM120.

VFDs adjust fan speed based on air demand, leading to:

- Energy savings

- Reduced mechanical wear

- Lower noise levels

- Plate Heat Exchangers

- Heat Pipes for Dehumidification & Heat Recovery

- Direct Expansion (DX) Coil: Used with refrigerants for cooling.

- Chilled Water Coil: Uses cold water for temperature control, commonly found in central cooling systems.

- Aluminum Filters (Reusable and washable)

- Synthetic Filters (Cost-effective but disposable)

- Pleated Filters (Higher dust-holding capacity)

- V-Filters (Low-velocity applications)

- Bag Filters (High-efficiency particle removal)

- HEPA Filters (For ultra-fine particle filtration)

- Carbon Filters (Odor and gas removal)