Cooling Tower Units

- Features a dry running fan for prolonged use.

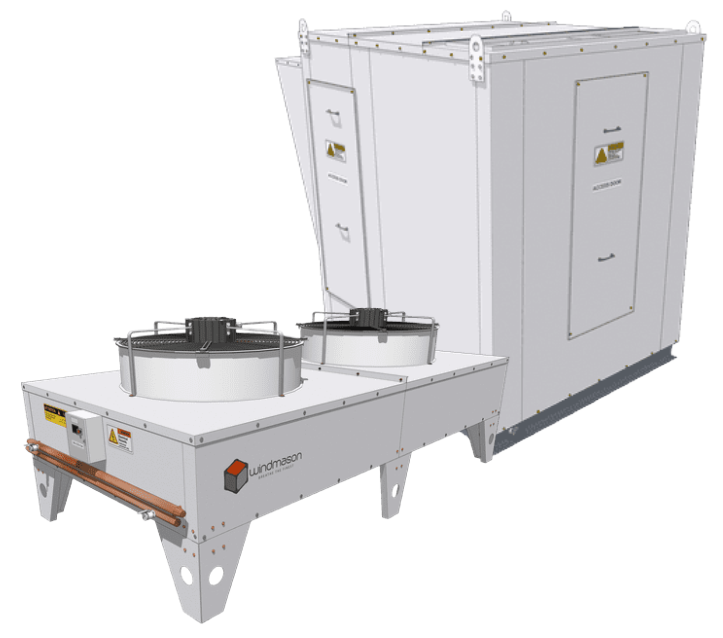

- Dry air cooling units with a high-efficiency axial fan.

- Offers both open loop and closed loop cooling towers.

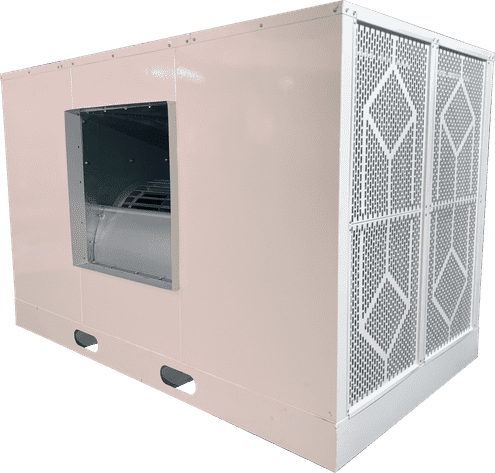

- Includes a backward centrifugal aluminium impeller direct drive fan.

- Air filter added for clean water and air, ensuring internal parts stay clean.

- Low maintenance for cooling media fills due to an external protective layer.

- Structures can be site-assembled or factory-assembled, with a modular design for larger capacities.

- Sturdy construction with metal-reinforced body panels and a water tank featuring a fiberglass inner layer.

Key Features

Cross Flow Cooling Tower (Open Loop)

Modular design with PVC fills, centrifugal fans, and efficient heat dissipation for HVAC and industrial cooling.

Cross Flow Cooling Tower (Closed Loop)

Uses copper heat exchange coils and evaporative cooling for refrigerant systems and process fluid cooling.

Evaporative Condenser Cooling Tower

High-efficiency cooling for refrigeration systems with corrosion-resistant copper tube aluminum fin coils.

Modular Design

All cooling towers can be installed in series/grid to increase capacity as per project requirements.

Dry Air-Cooling Unit

Water-free cooling system with copper/stainless steel coils, ideal for oil, gas, and industrial applications.

Corrosion-Resistant Materials

Casing, coils, and components are made from industrial-grade materials with anti-corrosion coatings for durability.

Major Components

Top Industries We Specialized in

Download Our Catalogue & Explore Energy-Saving Technologies.

From evaporative coolers to adiabatic solutions and industrial power solutions, explore everything we offer in one simple download.

Related Products

Frequently Asked Questions (FAQS)

They offer open-loop cross-flow cooling towers (WM-CTA), closed-loop cooling towers (WM-CTB), evaporative condenser cooling towers (WM-CTE), and dry air-cooling units (WM-CTD).

Yes, they can be installed in series or as an array to meet larger cooling capacity requirements.

WM-CTA (Open-Loop Cross Flow Cooling Tower)

It has a nominal capacity of 30 tons but can be scaled up with multiple units.

It ensures efficient airflow, prevents corrosion, and extends motor life by operating in a dry location.